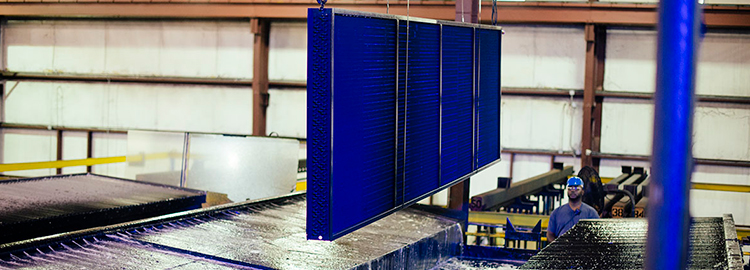

Corrosion Protection

When selecting the right cooler, corrosion protection is an important consideration. The site conditions, the outside environment, the liquid conditions inside the heat exchanger, the general operating conditions, and operational lifetime requirements will help to determine the required corrosion protection.

Modine’s paint system has been laboratory tested to ensure that our coolers have the longest possible service life and enjoy a reputation for reliability.

ElectroFin® E-Coat with C5 Classification

Modine’s ElectroFin® E-coat with UV topcoat guarantees corrosion protection and long-term reliability, and is suitable for both copper and aluminum parts. Coolers treated with ElectroFin® E-coat are corrosion resistant for over 15 years, even in the harshest environments. ElectroFin® E-coat is ideally suited for industrial areas with high humidity and hostile atmospheres, such as power plants, refineries, steam turbines, deserts, coastal and offshore areas with high salinity, and buildings or areas with nearly permanent condensation and high pollution.

ISO 12944 is the most comprehensive and frequently accepted standard and divides paint coatings into five corrosion protection classes. Classification C5 (Marine & Industrial/High Durability) is the highest certification for heat exchanger coatings in terms of application, performance, and durability.

It covers:

- Coating thickness and adhesion testing (ISO 2808 and ISO 2409)

- Long exposure in water and high-humidity atmospheres (ISO 2812 and ISO 6270)

- Salt-spray test and exposure to chemicals (ISO 9227 and ISO 2812)

Thickness of Coating

Thin coatings are better for heat transfer, while thick coatings can lead to diminished heat transfer and restricted airflow over the condenser coil. It’s important to remember that when fin spacing on condenser coils gets denser, a thick coating can cause fin bridging to occur, which severely restricts the efficiency of a condensing unit.

Corrosion 101

Corrosion is the destruction of material, usually metal or alloy, by chemical reaction with its environment. Corrosion can proceed in a general manner (general corrosion) or in a more localized manner (galvanic corrosion, pitting corrosion, formicary corrosion), depending on conditions and the material systems used. There are many types of corrosion; however, the most common types of corrosion within air conditioners are galvanic corrosion and general corrosion. Formicary corrosion also affects copper. These two corrosive processes can occur in as little as a few weeks after installation. More typically, corrosion will begin appearing within a one to four-year period. A protective coating will create a barrier between the metallic couple and the electrolyte, thereby eliminating the electrolyte, which is one of the causes for corrosion.